Take a Tour: Inside a Green Building

Certified Apparel Factory in Cambodia

With intensive awareness campaigns geared towards sustainable fashion, consumers are increasingly conscious about their buying decisions.

They prefer to support companies that make an effort to lessen their environmental footprint and behave ethically toward all their workers and

employees. In order to keep up, fashion brands implement stringent qualifications when choosing their supply chain partners, who adhere to

strict standards of social compliance and transparency.

Have you ever wondered what it s like inside a sustainable apparel factory? Let us take you on a tour around IK Apparel, a Green Building

Certified factory in Cambodia.

About IK Apparel

Nestled amid the lush green spaces of Le Urban Eco Park of Kandal Province, Cambodia, visitors will find the factory premises of IK Apparel Co. Ltd., spanning 16,160 sqm. Established by I Apparel International Group in May 2013, IK Apparel has grown to be the leading choice of some major global brands as their sustainable supply chain partner.

IK Apparel focuses on the construction of knitwear and woven products for men, women, and children. The factory specializes in the creation of Flame-Resistant (FR) and Snug Fit Sleepwear and Mix Fabrication Products. Highly sought-after sustainable fabrics such as organic cotton, recycled, and degradable content fabrics are available upon buyer's request. Every month, IK Apparel churns out millions of apparel pieces and exports them to reputable brands in the USA, Europe, and some countries in Asia. With no minimum order quantity required, IK Apparel works with brands of all sizes.

Green Building Certification

Coinciding with the completion of the factory’s solar panel installation, IK Apparel recently obtained the Building and Construction Authority (BCA)

Green Mark “Gold” Certificate for Non-residential Building.

The BCA Green Mark Scheme was launched in 2005 in Singapore. It is recognized internationally as a green building rating system specifically

designed to assess buildings constructed in a tropical climate; in four key areas of climate, resources, well-being, and ecology. Buildings should

possess design features that improve their ability to reduce carbon emissions and boost their resilience to the effects of climate change. They

should showcase efficient use and management of resources, such as the capacity to reuse water. More importantly, these buildings should

support and promote the health and well-being of the occupants. And finally, integrate nature in the building’s design and follow specific

measures to protect natural systems, including flora and fauna.

Depending on its performance, a building may obtain the highest rating of Green Mark Platinum. It is awarded to any structure that garners the

score of 70 and above. This is followed by the Green Mark GoldPlus, for those that scored 60 to less than 70, and the Green Mark Gold, for

those that fall under the scores of 50 to less than 60. Regardless of the rating though, any structure that obtains the Green Mark Certificate is

credibly excellent when it comes to environmental sustainability.

It takes foresight and careful planning to pass this certification. Bearing this in mind, I Apparel had the architectural design and construction of IK

Apparel factory created based on the requirements and standard set by the BCA.

“The process took around half a year from the conceptualization of the building and certification of the layout drawing and building materials to

the verification and assessment to ensure compliance with the building standard of BCA '', says I Apparel’s Sustainability Officer Rith Sovoitei.

For instance, the factory was designed to maximize natural ventilation and lighting. While there are no centralized air conditioning units, the

building efficiently reduces heat within its internal environment, making it conducive for productive work.

Many garment factories still use vertical steam boilers which could take a toll on surrounding forests because of their heavy reliance on wood

burning. Going against the norm, IK Apparel wanted to turn things around by acquiring induction steam boilers in place of vertical steam boilers.

This eliminates the need for massive wood cutting and burning. Additionally, it promotes up to 40% water recovery.

LED lights comprise 95% of the lighting needs of the building. What’s ideal about this type of lighting is that they last longer and use energy

more efficiently as opposed to conventional lighting.

Other sustainable features include the use of pneumatic automation machines in production which aids significant energy savings and cloudbased apparel production management and HR software applications to facilitate paperless functions.

Around late 2022, the installation of solar panels at the IK Factory started in full swing. The project lasted for around four months until it was completely finished in April 2023. Now, the 132 KWP on-grid solar rooftop system lines the 971.38 sqm of the new building’s rooftop and generates 40% of the factory’s total energy supply. While there’s not enough data for comparison yet, I Apparel remains confident that with the solar panel system in place, IK Apparel factory will see significant energy savings and carbon footprint reduction in the long-term.

“It will help us meet consumer demand in terms of a sustainable approach for low carbon products. As a supply chain partner, we will be more

attractive for brands that aim for low carbon suppliers to help them achieve their sustainability targets”, Rith comments when asked about the

significant benefits of sustainable features such as solar panels.

“It will contribute to achieve environmental goals and meet the global climate agenda by reducing greenhouse gas emissions”, she added.

Championing Social Care

Beyond conscious efforts on environmental sustainability, I Apparel champions social care–to benefit all of its employees and their families first, especially, the garment factory workers, and some chosen communities, second. This has become possible through I Apparel International Group’s corporate social foundation, the iCare Community Support (iCCS) Organization. Its active programs include the iCare Learning Center for education, the iCare Health Hub for healthcare, and the iCare Social Service for outreach projects benefiting chosen communities.

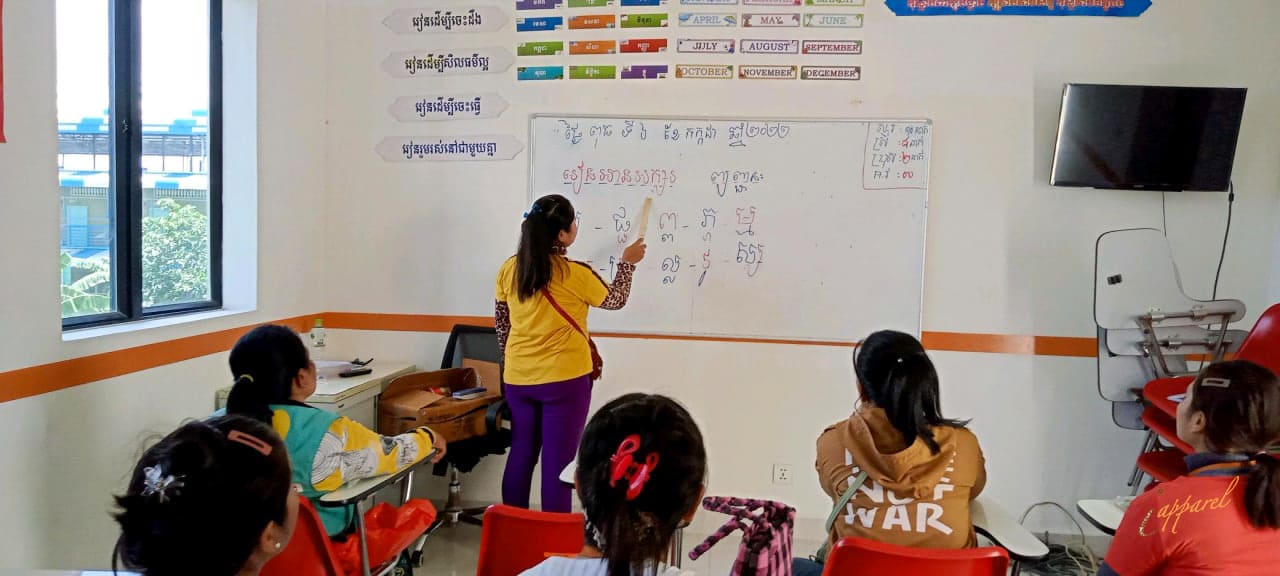

Employees are welcome to attend literacy courses at the iCare Learning Center. They are also encouraged to read more as books are readily available to borrow from the library located within the same facility. This educational program supports the government’s advocacy to boost Cambodia’s literacy rate. Moreover, as a personal goal, I Apparel hopes to provide equal opportunities to all its employees looking to advance their careers.

The iCare Health Hub, on the other hand, with a team of doctors and nurses on duty, provides health and wellness services all hours of the day

and all days of the week. Offering great convenience whether in times of emergency or just about any time the need for a medical check-up

arises, employees do not need to leave the premises of their workplace just to visit another hospital or clinic.

Meanwhile, iCCS leads charity drives and other types of outreach projects from time to time to extend its social care services to outside

communities. For example, the foundation donates cash and in-kind contributions to public schools, orphanages, and other individuals and

groups from marginalized sectors.

Future Goals

Achieving a Green Building Certificate is a crucial milestone. However, the work doesn’t stop there. Keeping this in mind, IK Apparel and the

entire I Apparel International Group commit to the continuing challenge of making the apparel industry friendlier to the planet. Aiming for zero

landfill waste, finding more ingenious ways to recycle fabric offcuts, reducing water consumption by up to 10% on the year 2023, and a significant

30% reduction of greenhouse gas emissions are just some of the major goals for the future that the company hopes to endeavor.

As of the moment, IK Apparel is rolling up its sleeves to hit the highest mark for industrial buildings within the next few years–that is, the BCA

Green Building Platinum Certificate.